VERNE® is designed to be fitted to a Remote Operated Vehicle (ROV) and combines two high-end complementary technologies: Long Range Ultrasonic Testing (LRUT) to gain a long range scanning ability in both direction from inspection point and Ultrasonic Normal Probe Array (UNPA) to achieve superior topographical information in defect characterization.

The purpose of LRUT is screening of pipelines or tubular structures in order to establish the presence or absence of defects. If LRUT proves that there are defects present at a given location, then the ROV will move the inspection unit to that specific location for detailed characterisation and sizing of the defect via UNPA.

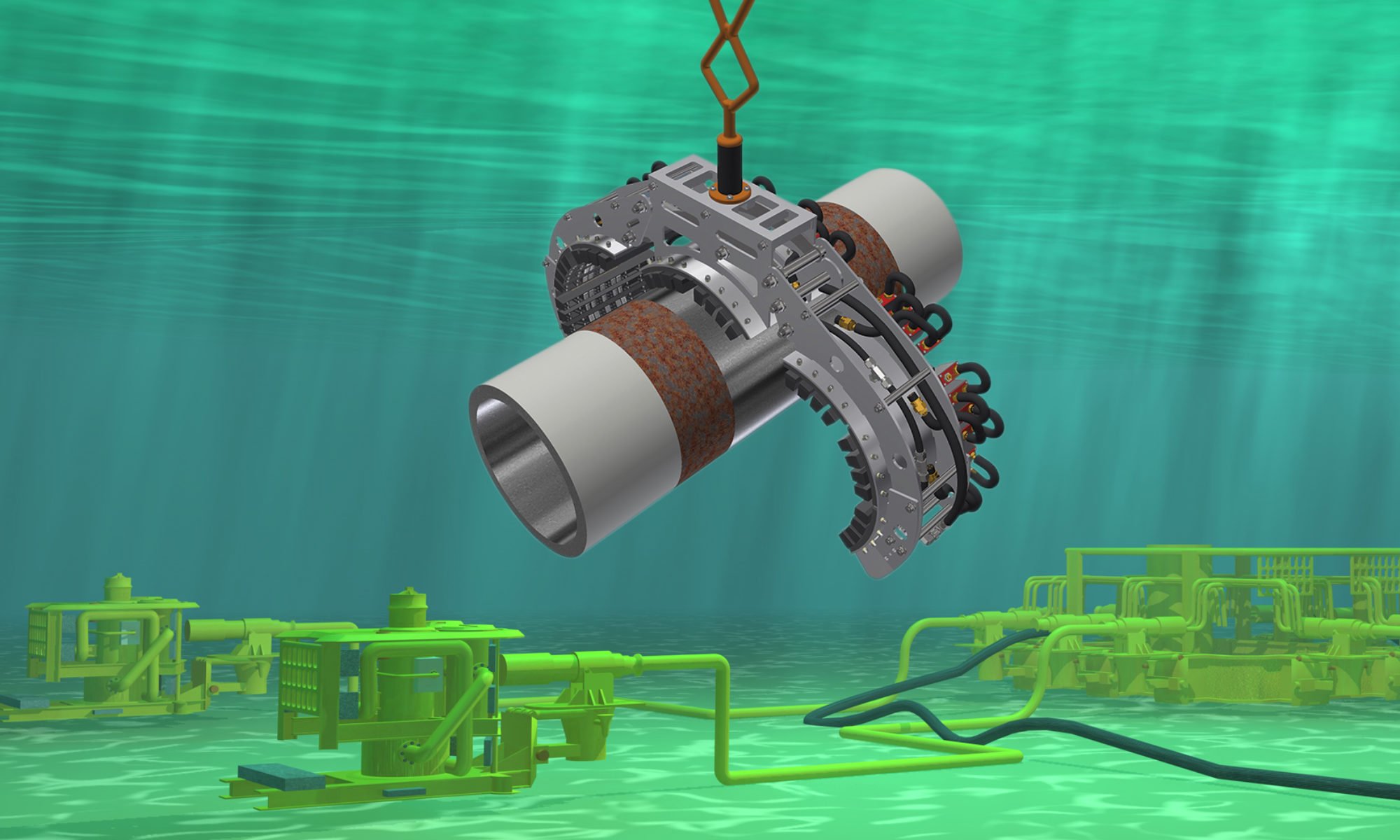

The compact light-weight NDT measurement tool is a modular system, combining a Clamp, a Hydraulic system and a Canister with electronics. With easy connection to the ROV by an ethernet cable and a standard fish-tail handle mounted on top of the VERNE® Clamp that fits to the ROV manipulator arm, and the VERNE® system is ready for use.

VERNE®, through rapid, automated, accurate, and cost-effective NDT, will be instrumental in addressing the urgent need for extending offshore asset lifetimes and postponing their costly decommissioning while eliminating the risk of catastrophic failures.

VERNE® INNOVATION: The project VERNE® originated as an European

Commission FP6 project primarly for LRUT inspection of Risers (2006-2008). The following SubCTest FP7 project aimed to use Alternating Current Field Measurement (ACFM) and Long Range Ultrasonic Testing (LRUT) sensors to inspect underwater pipelines and tubular structures. This project was finalized in a laboratory tank of the effectiveness of both types of sensors.

Subsequently, the project was offered a grant from the European Commission to validate the technology at Technology Readiness TRL7 and the follow-on project was entitled SubCTestDEMO. This project resulted in a prototype validated at TRL7 in a subsea environment using a work class ROV to test a subsea pipeline.

Following this successful outcome, in 2017, the two remaining SMEs Dacon AS and I&T Nardoni Instititute SRL were awarded a Horizon 2020 development project by the European Commission. The mandate of this project was to commercialize an NDT measurement instrument capable of screening tubular structures for loss of wall thickness in a subsea environment.

Based upon an extensive test program of both laboratory pool and open water tests, and in cooperation with an independent ROV manufacturer the VERNE® system has proven to be robust and reliable. Through close cooperation with TWI Ltd the VERNE® system has been validated to TRL9.

This project has received funding from the European Union’s Horizon 2020 – research and Innovation programme under the grant agreement No.778998